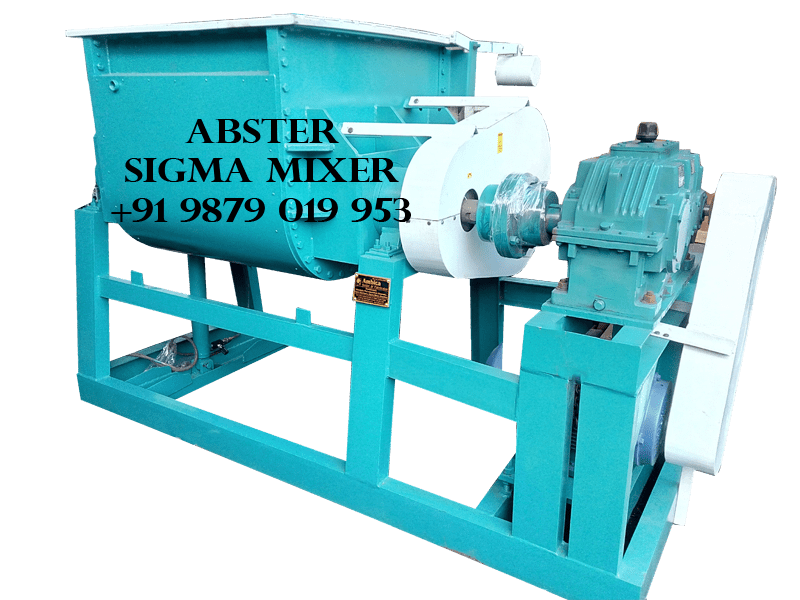

Specifications of Double Arm Mixer sigma mixer

| Gross Volume | Specified in cubic meters or liters |

| Working Volume | Specified in cubic meters or liters |

| Container Internal Dimensions | As per manufacturer's standerd |

| Container Shape | ?W? Sigma shaped |

Material of Construction as per requirment |

Product Contact parts, Non Contact Parts :

ASTM SA 240 Gr. 304/ Gr. 316 / Special Alloy Material Carbon Steel Confirming to ASTM A 36 / Equivalent |

| Jacket for Heat Transfer or Cooling (Optional) | Made from Carbon Steel Confirming to ASTM A 36 / Equivalent; ASTM SA 240, Gr. 304. Standard Design Pressure: As per process requirements |

| Container Cover(Options) |

Flat cover with Nozzles as required Dome shaped cover with Nozzles as requires Hinged |

| Stand structure | Material of Construction ? Structural Steel / Carbon Steel / Stainless Steel. Suitable to withstand dynamic load of mixer |

| Surface Finish |

|

| Mixing Blades(Options) | Profile :

Material of Construction :

CF 8 / CF 8M / CF 3 / CF 3M

|

| Bearing Housing | Bearing Housing with suitable bearings. |

| Seals (Options) |

|

| Drive | Standard

Optional

|

| Charging | Through Top Cover |

| Discharging | Through Top Cover by tilting of container |

| Container Tilting(Options) |

|

| Electricals | Electrical Control Panel provided with suitable Control Devices, Indicators, Switch Gears, Overload Protection, Safety Interlocks. |

| Overall Dimension | As per manufacturer?s catalog |

| Optional Features | GMP Equipment, Vacuum Operation, etc. |

Note: Above Specifications are for reference only and subject to change without prior notice. Kindly refer the manufacturer?s specifications for more details.